- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

What Makes Mattress Glue Essential for Durable and Comfortable Sleep?

2025-09-09

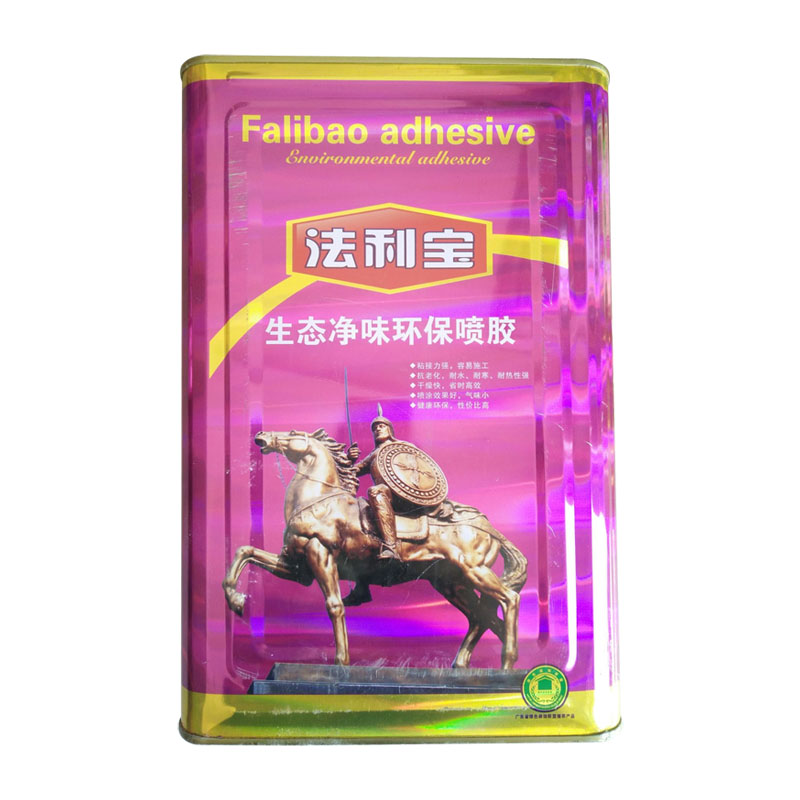

In the bedding and furniture industry, mattress glue plays a crucial role in ensuring comfort, durability, and structural integrity. As consumers become increasingly aware of the quality behind their mattresses, manufacturers are striving to use high-performance adhesives that deliver long-lasting results. Mattress glue, also known as mattress adhesive, is specially formulated to bond various layers of foam, fabric, springs, and other materials, creating a seamless and sturdy mattress structure.

What Is Mattress Glue and Why Is It Important?

A mattress is made of multiple components — foam layers, fabrics, coils, memory foam, latex, and even hybrid materials. Without a reliable adhesive, these layers would shift, warp, or separate over time. Mattress glue serves as the invisible backbone that ensures stability and comfort throughout the product’s lifecycle.

High-quality mattress adhesives are designed with specific performance goals:

-

Strong Bonding Strength – Prevents foam layers and fabrics from peeling or delaminating.

-

Flexibility – Allows the mattress to maintain its softness and elasticity without cracking the glue lines.

-

Safety and Low VOC – Non-toxic formulations ensure indoor air quality and user health.

-

Durability – Maintains adhesive performance even under pressure and prolonged use.

Types of Mattress Glue Commonly Used

| Type of Mattress Glue | Composition | Key Features | Best Use Case |

|---|---|---|---|

| Water-Based Adhesive | Acrylic/latex blend | Low VOC, eco-friendly, quick drying | Foam-to-foam bonding |

| Hot Melt Adhesive | Thermoplastic polymers | Instant bonding, solvent-free | Fast production lines |

| Solvent-Based Adhesive | Synthetic rubber-based | Superior bonding strength, heat-resistant | Heavy-duty mattress designs |

| Sprayable Adhesive | Various bases | Even application, reduces waste | Large-scale mattress assembly |

By choosing the right adhesive type, manufacturers can balance production efficiency, environmental safety, and end-user comfort.

How Does Mattress Glue Enhance Comfort and Durability?

Mattress glue isn’t just about keeping layers together — it directly impacts the sleep experience and the overall lifecycle of the mattress. Poor-quality adhesives can cause multiple issues, from uneven surfaces to reduced mattress lifespan.

Here’s how a high-quality adhesive makes a difference:

a) Prevents Layer Separation

One of the main causes of mattress failure is layer delamination. Premium adhesives maintain consistent bonding strength, ensuring foam, coils, and fabrics stay perfectly aligned.

b) Supports Ergonomic Design

Modern mattresses often feature zoned support systems, combining multiple foam densities to relieve pressure points. Strong yet flexible glue ensures these zones remain intact, delivering personalized comfort for years.

c) Improves Production Efficiency

Fast-curing adhesives speed up manufacturing without compromising quality. Water-based and hot melt adhesives are especially effective in automated production lines.

d) Enhances Safety and Sustainability

Low-VOC, non-toxic mattress adhesives are compliant with global safety regulations such as CertiPUR-US®, OEKO-TEX®, and REACH. This ensures healthier indoor environments and aligns with eco-friendly manufacturing trends.

Technical Specifications of Our Mattress Glue

Our Runfeng mattress glue is engineered for precision, high performance, and safety. Below are the key technical parameters that define its superior bonding capabilities:

| Property | Specification | Benefit |

|---|---|---|

| Base Material | Water-based acrylic | Eco-friendly, safe for indoor use |

| Viscosity | 3,500 – 4,200 cps | Optimal sprayability for consistent coverage |

| Solid Content | 45% ± 2% | Strong bonding with minimal material usage |

| Drying Time | 30–45 seconds | Speeds up assembly and production |

| Bond Strength | ≥ 2.5 MPa | Ensures long-term durability |

| Heat Resistance | Up to 90°C | Maintains integrity even under high temperatures |

| VOC Emissions | < 50 g/L | Meets international environmental standards |

This combination of strong bonding power, fast curing, and low emissions makes Runfeng mattress glue ideal for both large-scale manufacturing and premium mattress designs.

Why Choose High-Quality Mattress Glue for Your Business

In today’s competitive bedding market, consumer expectations are rising. Comfort, durability, and safety are no longer optional — they are essential. Manufacturers who choose inferior adhesives risk product recalls, negative customer reviews, and reduced brand reputation.

Advantages of Premium Mattress Adhesives

-

Extended Product Lifespan – Mattresses stay intact for years without sagging or separating.

-

Enhanced Customer Satisfaction – A well-bonded mattress maintains its original comfort and support.

-

Reduced Production Costs – Reliable adhesives minimize defects and waste.

-

Eco-Friendly Manufacturing – Low-VOC and solvent-free formulas meet green compliance demands.

-

Global Certification Compliance – Safe for export and international trade.

By integrating advanced adhesive technology, manufacturers can maintain a competitive edge while delivering products that meet strict environmental and safety standards.

Frequently Asked Questions About Mattress Glue

Q1: Is mattress glue safe for home use and indoor environments?

A1: Yes. Our water-based mattress glue is specifically formulated to meet low-VOC standards and comply with strict safety regulations, such as OEKO-TEX® and CertiPUR-US®. It contains no harmful solvents and emits minimal odor, making it safe for bedrooms, nurseries, and other indoor environments.

Q2: How long does mattress glue last, and does it affect mattress comfort over time?

A2: When applied correctly, high-quality mattress glue can last for the entire life of the mattress — typically 8 to 12 years. The adhesive remains flexible, ensuring that it doesn’t harden or crack, which preserves the original comfort and ergonomic performance of the mattress throughout its lifespan.

Partner with Runfeng for Superior Mattress Adhesives

At Runfeng, we specialize in developing high-performance mattress adhesives that combine strength, safety, and efficiency. Our solutions are trusted by leading bedding manufacturers worldwide to create products that stand out in quality and durability.

Whether you’re looking to improve your production process, meet environmental compliance standards, or deliver premium comfort to your customers, Runfeng mattress glue is your ideal choice.

Contact us today to discuss your adhesive requirements and discover how we can help you elevate your mattress manufacturing.